Tungsten Carbide tapered tungtung Mill

Fitur

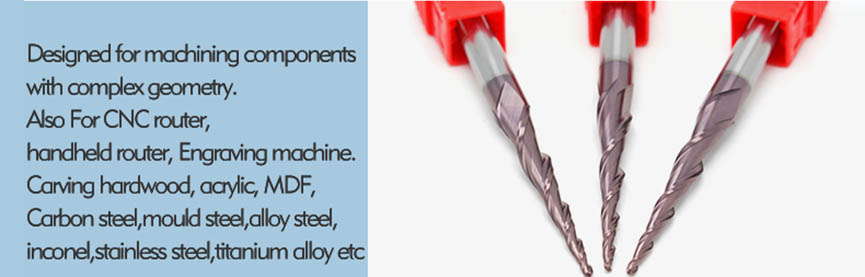

1. Kamampuhan machining serbaguna: pabrik tungtung tapered bisa dipaké pikeun rupa-rupa operasi machining, kaasup contouring, slotting, sarta pangeboran. Desain taper ngamungkinkeun pikeun panyabutan bahan efisien sarta motong tepat dina sababaraha arah.

2. Ningkatkeun aksés jeung jangkauan: Bentuk tapered tina ngagiling tungtung nyadiakeun aksés hadé ka wewengkon susah-to-ngahontal tur ngamungkinkeun pikeun operasi panggilingan jero. Ieu hususna nguntungkeun nalika damel sareng bagian kompléks atanapi jero rohangan.

3. Évakuasi chip ditingkatkeun: Desain suling tina pabrik tungtung tapered mantuan pikeun évakuasi chip éfisién. Kalayan volume suling anu langkung ageung sareng jarak anu langkung lega, aranjeunna mujarab pikeun ngaleungitkeun chip tina daérah motong, ngirangan résiko recutting chip sareng ningkatkeun kamampuan alat sacara umum.

4. Ngaronjat stabilitas jeung rigidity: Tungsten carbide tapered pabrik tungtung nu dirancang pikeun nyadiakeun ngaronjat stabilitas jeung rigidity salila motong. Bentuk kerucut mantuan pikeun ngadistribusikaeun gaya motong leuwih merata, ngurangan geter jeung ngaminimalkeun deflection, hasilna ningkat akurasi sarta finish permukaan.

5. Sababaraha sudut taper sadia: Mills tungtung tapered datangna dina sagala rupa sudut taper, kayaning 3 °, 5 °, 7 °, sarta leuwih. Pilihan sudut taper gumantung kana sarat aplikasi husus, kayaning diaméter motong dipikahoyong tur bahan keur machined.

6. pilihan palapis: Tungsten carbide tapered pabrik tungtung bisa coated kalawan rupa coatings, kayaning TiAlN, TiCN, atawa AlTiN, jang meberkeun ningkatkeun kinerja maranéhanana. Coatings nyadiakeun kahirupan alat ngaronjat, ngurangan gesekan, sarta ningkat lalawanan panas, gumantung kana palapis husus dilarapkeun.

tampilan jéntré

PABRIK

| Dua suling spiral tapered ball irung tungtung Mills | |||||

| lumaku: Aluminium, plastik, bagian plastik, bagian tambaga, alloy aluminium, kapang stainless steel, kai | |||||

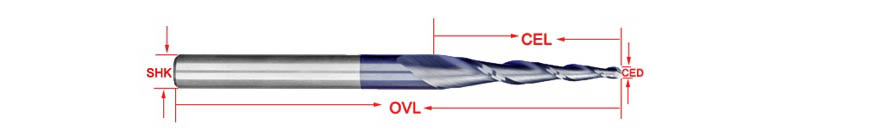

| NO | SHK | 1/2 CED (mm) | CEL | OVL | |

| 2fbn30.2515 | 3.175 | 0.25 | 15 | 38.5 | |

| 2fbn30.515 | 3.175 | 0.5 | 15 | 38.5 | |

| 2fbn30.7515 | 3.175 | 0.75 | 15 | 38.5 | |

| 2fbn31.015 | 3.175 | 1 | 15 | 38.5 | |

| 2fbn40.2515 | 4 | 0.25 | 15 | 50 | |

| 2fbn40.515 | 4 | 0.5 | 15 | 50 | |

| 2fbn40.7515 | 4 | 0.75 | 15 | 50 | |

| 2fbn41.015 | 4 | 1 | 15 | 50 | |

| 2fbn40.2520.5 | 4 | 0.25 | 20.5 | 50 | |

| 2fbn40520.5 | 4 | 0.5 | 20.5 | 50 | |

| 2fbn40.7520.5 | 4 | 0.75 | 20.5 | 50 | |

| 2fbn41.020.5 | 4 | 1 | 20.5 | 50 | |

| 2fbn60.2520.5 | 6 | 0.25 | 20.5 | 50 | |

| 2fbn60.520.5 | 6 | 0.5 | 20.5 | 50 | |

| 2fbn60.7520.5 | 6 | 0.75 | 20.5 | 50 | |

| 2fbn61.020.5 | 6 | 1 | 20.5 | 50 | |

| 2fbn602530.5 | 6 | 0.25 | 30.5 | 75 | |

| 2fbn60.530.5 | 6 | 0.5 | 30.5 | 75 | |

| 2fbn60.7530.5 | 6 | 0.75 | 30.5 | 75 | |

| 2fbn61.030.5 | 6 | 1 | 30.5 | 75 | |

| 2fbn61.530.5 | 6 | 1.5 | 30.5 | 75 | |

| 2fbn62.030.5 | 6 | 2 | 30.5 | 75 | |

| 2fbn80.547 | 8 | 0.5 | 47 | 85 | |

| 2fbn81.047 | 8 | 1 | 47 | 85 | |

| 2fbn81.547 | 8 | 1.5 | 47 | 85 | |

| 2fbn82047 | 8 | 2 | 47 | 85 | |

| 2fbn80.560 | 8 | 0.5 | 60 | 100 | |

| 2fbn81.060 | 8 | 1 | 60 | 100 | |

| 2fbn81.560 | 8 | 1.5 | 60 | 100 | |

| 2fbn82.060 | 8 | 2 | 60 | 100 | |

| 2fbn10270 | 10 | 2 | 70 | 110 | |

| 2fbn12270 | 12 | 2 | 70 | 120 | |