DIN338 pinuh Ground HSS M2 pulas bor bit

Fitur

The DIN338 pinuh taneuh HSS M2 twist drill bit boga sababaraha fitur beredar, kaasup:

High Speed Steel (HSS) M2 Bahan: Pamakéan bahan HSS M2 nyadiakeun karasa unggul, résistansi ngagem, sarta lalawanan panas, sahingga bit bor ieu cocog pikeun pangeboran rupa-rupa bahan, kaasup stainless steel, baja alloy, sarta bahan non-logam. logam hideung.

FUTES GROUND FLUTES AND CUTTING EDGES: The bor bit nyaéta taneuh precision nyadiakeun alur seukeut tur konsisten tur motong edges, hasilna évakuasi chip ningkat, ngurangan gesekan jeung ngaronjat akurasi pangeboran.

Titik pamisah 135 derajat: Bit bor ngadopsi desain titik pamisah 135 derajat, anu ngabantosan ngirangan kabutuhan liang pilot, ningkatkeun kamampuan centering sareng timer centering, sareng ningkatkeun efisiensi pangeboran.

FINISH GLOSSY: The finish caang dina bit bor resists korosi, promotes aliran chip, sarta nyadiakeun pisibilitas ditingkatkeun salila operasi, mantuan pikeun ngaronjatkeun kinerja sarta hirup layanan.

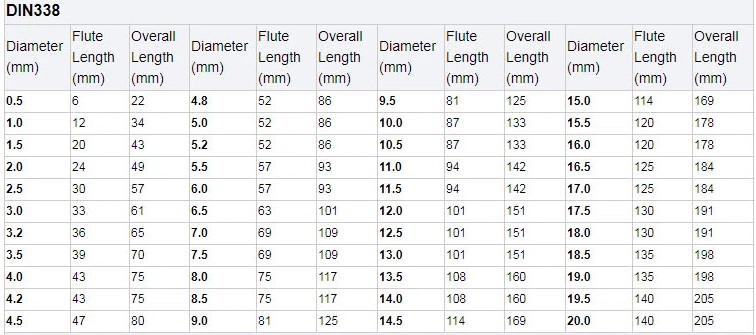

DIN338 patuh: Drills sasuai jeung standar DIN338, mastikeun dimensi konsisten, manufaktur kualitas luhur, sarta minuhan standar industri pikeun akurasi jeung reliabilitas.

Aplikasi serbaguna: bit bor pulas ieu cocog pikeun tugas pangeboran umum dina rupa-rupa bahan, sahingga serbaguna tur praktis pikeun rupa-rupa aplikasi pangeboran.

Umur alat panjang: Kombinasi bahan HSS M2 kualitas luhur, grinding precision sareng desain awét ngabantosan manjangkeun umur alat sareng ngirangan frekuensi ngagantian sareng pangropéa.

Kalawan babarengan, fitur ieu ngajadikeun DIN338 pinuh taneuh HSS M2 pulas bor bit a dipercaya,-kinerja tinggi alat pikeun aplikasi pangeboran profésional sarta industri.

acara PRODUK

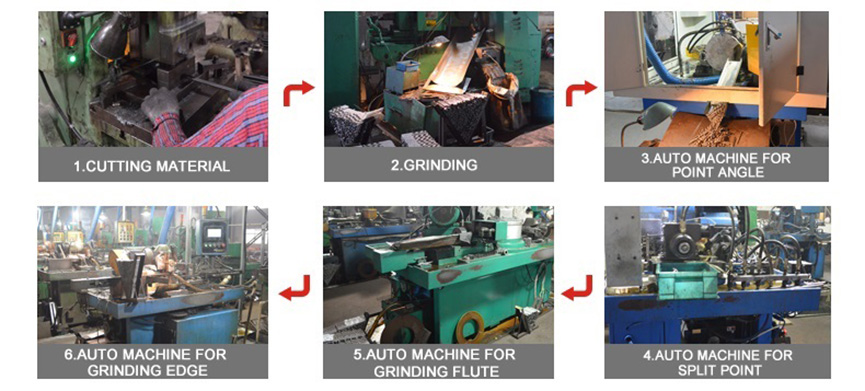

ALIRAN PROSES

Kaunggulan

DIN338 pinuh taneuh HSS M2 pulas bor bit nawarkeun rupa-rupa kaunggulan, kaasup:

Daya Tahan Tinggi: Bahan HSS M2 nyayogikeun karasa punjul sareng résistansi ngagem pikeun daya tahan anu tahan panjang, khususna nalika ngabor bahan anu kuat sapertos stainless steel, baja alloy sareng logam non-ferrous.

Precision jeung Akurasi: Flutes taneuh pinuh sarta motong edges mastikeun kinerja pangeboran tepat tur konsisten, ngahasilkeun bersih, liang akurat.

évakuasi chip efisien: alur taneuh Precision sarta motong edges mempermudah évakuasi chip efisien, ngaminimalkeun clogging sarta ngaronjatkeun efisiensi pangeboran.

Ningkatkeun kagancangan pangeboran: Desain titik pamisah 135-derajat ngaminimalkeun kabutuhan pra-pangeboran, ngamungkinkeun pangeboran langkung gancang sareng ningkat produktivitas.

Ngurangan panas jeung gesekan: bahan baja-speed tinggi na grinding precision mantuan ngurangan panas ngawangun-up sarta gesekan salila pangeboran, hasilna operasi smoother tur umur alat leuwih panjang.

Résistansi Korosi: Beungeut anu terang dina bit bor nyaéta tahan korosi, manjangkeun umur bor sareng ngajaga kinerja motong na. Versatility: bor bit ieu cocog pikeun rupa-rupa aplikasi pangeboran, sahingga serbaguna tur praktis pikeun pamakéan dina rupa-rupa bahan jeung industri.

Ku delivering kaunggulan ieu, DIN338 pinuh taneuh HSS M2 pulas bor bit delivers reliabiliti, efisiensi tur umur panjang dina operasi pangeboran.

| DIN338 HSS TWIST bor bit | ||||||||

| Diaméterna (mm) | Suling Panjang (mm) | Gemblengna Panjang (mm) | Diaméterna (mm) | Suling Panjang (mm) | Gemblengna Panjang (mm) | Diaméterna (mm) | Suling Panjang (mm) | Gemblengna Panjang (mm) |

| 0.2 | 2.5 | 19.0 | 5.6 | 57.0 | 93.0 | 11.0 | 94.0 | 142.0 |

| 0.3 | 3.0 | 19.0 | 5.7 | 57.0 | 93.0 | 11.1 | 94.0 | 142.0 |

| 0.4 | 5.0 | 20.0 | 5.8 | 57.0 | 93.0 | 11.2 | 94.0 | 142.0 |

| 0.5 | 6.0 | 22.0 | 5.9 | 57.0 | 93.0 | 11.3 | 94.0 | 142.0 |

| 0.6 | 7.0 | 24.0 | 6.0 | 57.0 | 93.0 | 11.4 | 94.0 | 142.0 |

| 0.7 | 9.0 | 28.0 | 6.1 | 63.0 | 101.0 | 11.5 | 94.0 | 142.0 |

| 0.8 | 10.0 | 30.0 | 6.2 | 63.0 | 101.0 | 11.6 | 94.0 | 142.0 |

| 0.9 | 11.0 | 32.0 | 6.3 | 63.0 | 101.0 | 11.7 | 94.0 | 142.0 |

| 1.0 | 12.0 | 34.0 | 6.4 | 63.0 | 101.0 | 11.8 | 94.0 | 142.0 |

| 1.1 | 14.0 | 36.0 | 6.5 | 63.0 | 101.0 | 11.9 | 101.0 | 151.0 |

| 1.2 | 16.0 | 38.0 | 6.6 | 63.0 | 101.0 | 12.0 | 101.0 | 151.0 |

| 1.3 | 16.0 | 38.0 | 6.7 | 63.0 | 101.0 | 12.1 | 101.0 | 151.0 |

| 1.4 | 18.0 | 40.0 | 6.8 | 69.0 | 109.0 | 12.2 | 101.0 | 151.0 |

| 1.5 | 18.0 | 40.0 | 6.9 | 69.0 | 109.0 | 12.3 | 101.0 | 151.0 |

| 1.6 | 20.0 | 43.0 | 7.0 | 69.0 | 109.0 | 12.4 | 101.0 | 151.0 |

| 1.7 | 20.0 | 43.0 | 7.1 | 69.0 | 109.0 | 12.5 | 101.0 | 151.0 |

| 1.8 | 22.0 | 46.0 | 7.2 | 69.0 | 109.0 | 12.6 | 101.0 | 151.0 |

| 1.9 | 22.0 | 46.0 | 7.3 | 69.0 | 109.0 | 12.7 | 101.0 | 151.0 |

| 2.0 | 24.0 | 49.0 | 7.4 | 69.0 | 109.0 | 12.8 | 101.0 | 151.0 |

| 2.1 | 24.0 | 49.0 | 7.5 | 69.0 | 109.0 | 12.9 | 101.0 | 151.0 |

| 2.2 | 27.0 | 53.0 | 7.6 | 75.0 | 117.0 | 13.0 | 101.0 | 151.0 |

| 2.3 | 27.0 | 53.0 | 7.7 | 75.0 | 117.0 | 13.1 | 101.0 | 151.0 |

| 2.4 | 30.0 | 57.0 | 7.8 | 75.0 | 117.0 | 13.2 | 101.0 | 151.0 |

| 2.5 | 30.0 | 57.0 | 7.9 | 75.0 | 117.0 | 13.3 | 108.0 | 160.0 |

| 2.6 | 30.0 | 57.0 | 8.0 | 75.0 | 117.0 | 13.4 | 108.0 | 160.0 |

| 2.7 | 33.0 | 61.0 | 8.1 | 75.0 | 117.0 | 13.5 | 108.0 | 160.0 |

| 2.8 | 33.0 | 61.0 | 8.2 | 75.0 | 117.0 | 13.6 | 108.0 | 160.0 |

| 2.9 | 33.0 | 61.0 | 8.3 | 75.0 | 117.0 | 13.7 | 108.0 | 160.0 |

| 3.0 | 33.0 | 61.0 | 8.4 | 75.0 | 117.0 | 13.8 | 108.0 | 160.0 |

| 3.1 | 36.0 | 65.0 | 8.5 | 75.0 | 117.0 | 13.9 | 108.0 | 160.0 |

| 3.2 | 36.0 | 65.0 | 8.6 | 81.0 | 125.0 | 14.0 | 108.0 | 160.0 |

| 3.3 | 36.0 | 65.0 | 8.7 | 81.0 | 125.0 | 14.3 | 114.0 | 169.0 |

| 3.4 | 39.0 | 70.0 | 8.8 | 81.0 | 125.0 | 14.5 | 114.0 | 169.0 |

| 3.5 | 39.0 | 70.0 | 8.9 | 81.0 | 125.0 | 14.8 | 114.0 | 169.0 |

| 3.6 | 39.0 | 70.0 | 9.0 | 81.0 | 125.0 | 15.0 | 114.0 | 169.0 |

| 3.7 | 39.0 | 70.0 | 9.1 | 81.0 | 125.0 | 15.3 | 120.0 | 178.0 |

| 3.8 | 43.0 | 75.0 | 9.2 | 81.0 | 125.0 | 15.5 | 120.0 | 178.0 |

| 3.9 | 43.0 | 75.0 | 9.3 | 81.0 | 125.0 | 15.8 | 120.0 | 178.0 |

| 4.0 | 43.0 | 75.0 | 9.4 | 81.0 | 125.0 | 16.0 | 120.0 | 178.0 |

| 4.1 | 43.0 | 75.0 | 9.5 | 81.0 | 125.0 | 16.3 | 125.0 | 184.0 |

| 4.2 | 43.0 | 75.0 | 9.6 | 87.0 | 133.0 | 16.5 | 125.0 | 184.0 |

| 4.3 | 47.0 | 80.0 | 9.7 | 87.0 | 133.0 | 16.8 | 125.0 | 184.0 |

| 4.4 | 47.0 | 80.0 | 9.8 | 87.0 | 133.0 | 17.0 | 125.0 | 184.0 |

| 4.5 | 47.0 | 80.0 | 9.9 | 87.0 | 133.0 | 17.3 | 130.0 | 191.0 |

| 4.6 | 47.0 | 80.0 | 10.0 | 87.0 | 133.0 | 17.5 | 130.0 | 191.0 |

| 4.7 | 47.0 | 80.0 | 10.1 | 87.0 | 133.0 | 17.8 | 130.0 | 191.0 |

| 4.8 | 52.0 | 86.0 | 10.2 | 87.0 | 133.0 | 18.0 | 130.0 | 191.0 |

| 4.9 | 52.0 | 86.0 | 10.3 | 87.0 | 133.0 | 18.5 | 135.0 | 198.0 |

| 5.0 | 52.0 | 86.0 | 10.4 | 87.0 | 133.0 | 18.8 | 135.0 | 198.0 |

| 5.1 | 52.0 | 86.0 | 10.5 | 87.0 | 133.0 | 19.0 | 135.0 | 198.0 |

| 5.2 | 52.0 | 86.0 | 10.6 | 87.0 | 133.0 | 19.3 | 140.0 | 205.0 |

| 5.3 | 52.0 | 86.0 | 10.7 | 94.0 | 142.0 | 19.5 | 140.0 | 205.0 |

| 5.4 | 57.0 | 93.0 | 10.8 | 94.0 | 142.0 | 19.8 | 140.0 | 205.0 |

| 5.5 | 57.0 | 93.0 | 10.9 | 94.0 | 142.0 | 20.0 | 140.0 | 205.0 |